SECO/WARWICK offers professional maintenance services for metal heat treatment and metallurgy equipment. We offer comprehensive and specialized service operating all over the world, including industrial furnaces from other manufacturers!

If you are looking for a reliable and professional partner for long-term service cooperation, bet on the SECO/WARWICK Group. Our service engineer’s knowledge and experience allow for the effective management of a metal heat treatment equipment facility. Regardless of who the manufacturer of your equipment is, our service offer is comprehensive and combined with a well-stocked spare parts warehouse.

98%

CUSTOMERS RECOMMEND OUR SERVICE

8

SERVICE CENTERS

100

SERVICE TECHNICIANS WORLDWIDE

1

ONLY OFFER

COOPERATION WITH THE SECO/WARWICK SERVICE MEANS SOMETHING MORE!

We increase the reliability of equipment by using automated procedures and providing services including maintenance, remote acceptance, technical and design support, renovations, modernizations, and relocations of furnaces. Our service includes regular preventive inspections and preventive actions, as well as advanced measurement and reporting tools.

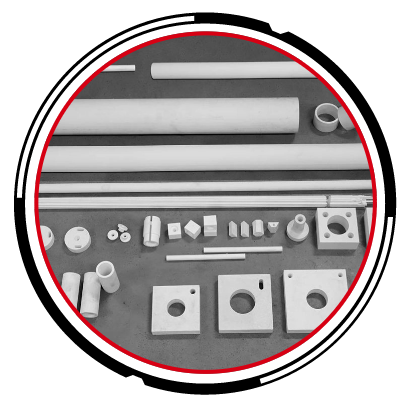

SECO/PARTTECH

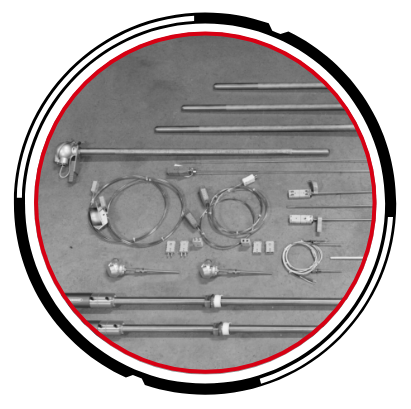

SECO/LABTECH

Thanks to us, you will discover the secret of reliable equipment operation and receive technical support at every stage of the process.

DISCOVER OUR SERVICE AND PRODUCTION

SECO/WARWICK professional maintenance service

If you are looking for an experienced service team, with the highest level of knowledge available worldwide, we are unrivaled in the field of metal heat treatment and metallurgy.

Every year, SECO/WARWICK conducts satisfaction surveys among its customers. This year’s results leave no doubt – SECO/WARWICK is the first choice among specialist services. Our customer satisfaction surveys demonstrate that as many as 98 percent of customers would recommend the SECO/WARWICK service team. Customers particularly appreciate the service quality, the service engineer’s professionalism and knowledge along with the service offer’s comprehensiveness. Customers are partners in discovering and implementing the best possible solutions for their business.

Professional Maintenance Services provided by SECO/WARWICK are more than just repairs in the event of a breakdown. We understand furnaces, enabling our team to increase their availability using automated maintenance processes. We provide design and technological support for repairs, modernizations and relocations, following up with preventive inspections and preventive actions. In addition, we offer advanced tools for measurement and reporting.

Service engineers visit customers from 8 service centers on three continents. This guarantees a fast response, which is critical in the event of equipment failure.

Services for industrial furnaces and metal heat treatment equipment

SECO/WARWICK service covers industrial furnaces and metal heat treatment equipment from most manufacturers. The service offered will meet the required safety standards, and are carried out in accordance with the NADCAP standard.

The engineering team also offers comprehensive technical inspections of heat treatment and vacuum metallurgy furnaces, including regular monitoring of equipment operation, measurement of their efficiency and tightness, and ongoing technical support under service contracts.

Renovations and modernizations - comprehensive support for your equipment operation

Our service engineers have an in-depth knowledge in the field of repairing and servicing furnaces. They have access to the latest, advanced tools and technologies, which allows them to diagnose and solve any technical problems quickly and effectively. Whether you need emergency repairs, regular furnace maintenance, or equipment upgrades, our experts are ready to meet your needs.

An existing industrial equipment facility modernization is a key step in ensuring the continued efficiency and effectiveness of these furnaces. The SECO/SERVICE experienced team is ready to carry out comprehensive modernization, tailored to your individual needs.

The team will comprehensively deal with modernization and propose the most effective renovation solutions which will improve the equipment efficiency, including units from other manufacturers.