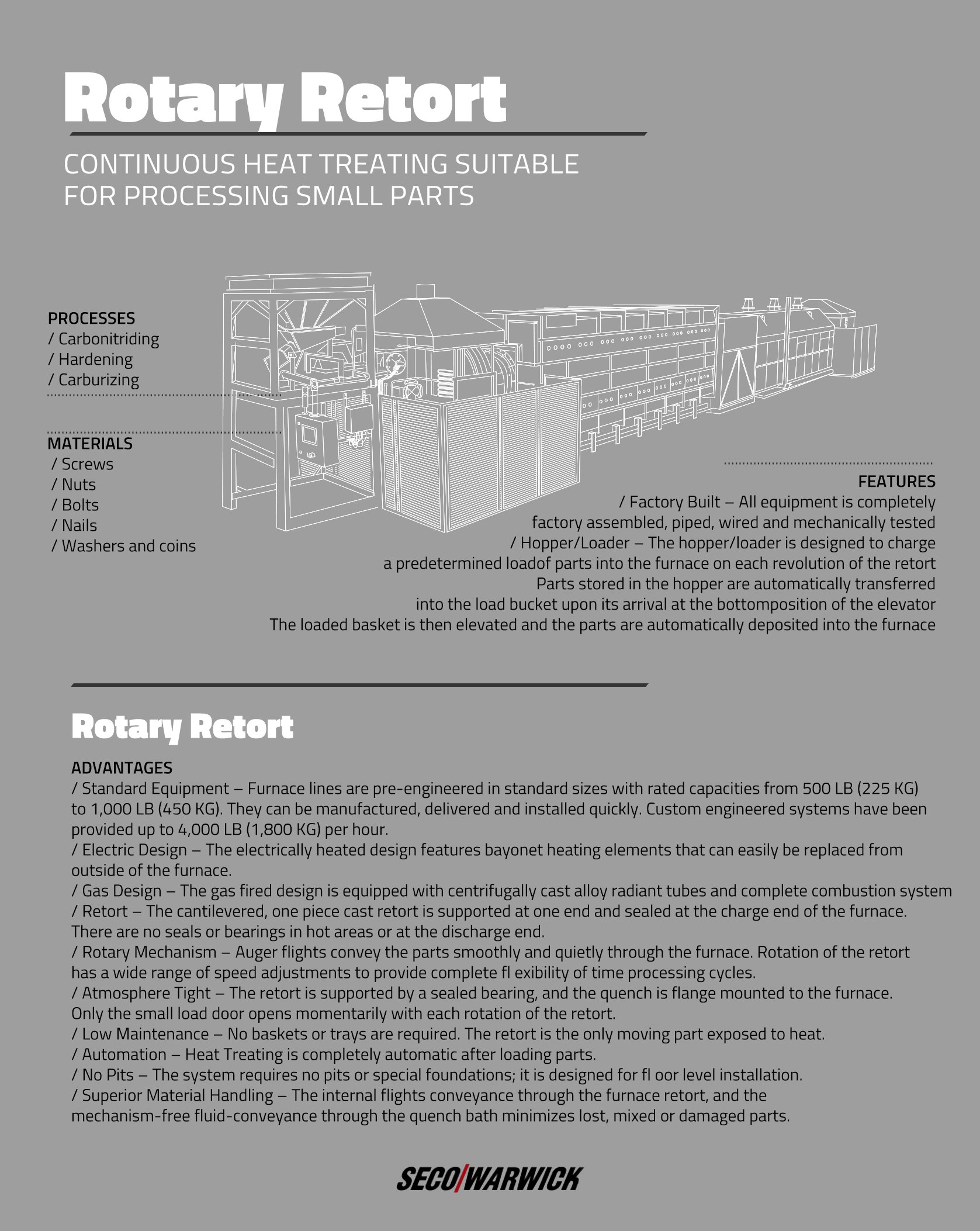

Rotary Retort Furnace Systems

Continuous Heat Treating suitable for processing small parts

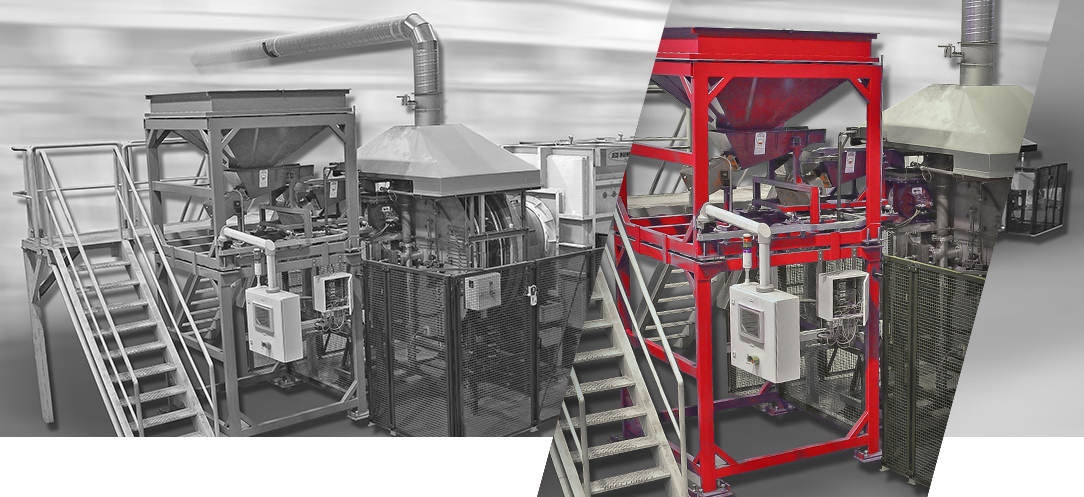

SECO/WARWICK’s rotary retort furnaces are specifically designed for continuous production and uniform heat treating of small parts, such as coins, small hardware, nails, bearings, chain components, and fasteners, such as nuts, bolts, and screws.

The rotary retort furnace is designed to improve production and maintain the consistent heat treating and quench performance required in high-performance small parts like bearings and fasteners. It provides the process flexibility to be utilized for either single or multi-application production environments and in small or large batches. SECO/WARWICK customers are choosing Rotary Retort systems to save time and money in maintenance and operating costs when evaluating the total cost of ownership compared to traditional mesh belt or batch systems.

Whirl-A-Way Quench™

The Whirl-A-Way quench is a fast uniform quenching system that produces deeper case depths.The Whirl-A-Way quench is designed to provide superior quench results with ferrous and nonferrous parts after they have reached temperature in the furnace. Parts are discharged into the quench medium seconds after temperature has been achieved and are conveyed to the rotating discharge conveyor by the motion of the quench fluid. This motion allows the vapor barrier of each part to be instantaneously wiped away, resulting in excellent quench properties. On entry into the quench drum, parts are conveyed to the discharge point by the revolving motion of the drum flights. The quench fluid can be oil, water or synthetic media. The patented Whirl-A-Way system is designed to prevent atmosphere contamination in the furnace. The system is capable of handling a wide variety of part configurations while constantly maintaining individual quench results, providing both deeper case depths and uniformity

/ Hopper/Loader – The hopper/loader is designed to charge a predetermined load of parts into the furnace on each revolution of the retort. Parts stored in the hopper are automatically transferred into the load bucket upon its arrival at the bottom position of the elevator. The loaded basket is then elevated and the parts are automatically deposited into the furnace.

/ Electric Design – The electrically heated design features bayonet heating elements that can easily be replaced from outside of the furnace.

/ Gas Design – The gas fired design is equipped with centrifugally cast alloy radiant tubes and complete combustion system

.

/ Retort – The cantilevered, one piece cast retort is supported at one end and sealed at the charge end of the furnace. There are no seals or bearings in hot areas or at the discharge end.

/ Rotary Mechanism – Auger flights convey the parts smoothly and quietly through the furnace. Rotation of the retort has a wide range of speed adjustments to provide complete fl exibility of time processing cycles.

/ Atmosphere Tight – The retort is supported by a sealed bearing, and the quench is flange mounted to the furnace. Only the small load door opens momentarily with each rotation of the retort.

/ Low Maintenance – No baskets or trays are required. The retort is the only moving part exposed to heat.

/ Automation – Heat Treating is completely automatic after loading parts.

/ No Pits – The system requires no pits or special foundations; it is designed for fl oor level installation.

/ Superior Material Handling – The internal flights conveyance through the furnace retort, and the mechanism-free fluid-conveyance through the quench bath minimizes lost, mixed or damaged parts.

/ Hardening,

/ Carburizing.

/ Screws,

/ Nuts,

/ Bolts,

/ Nails,

/ Washers and coins.